When pricing channel letter signs, you'll consider several factors like size, materials, and installation. Larger signs need more materials and labor, and local laws can also influence costs. Choosing between materials like aluminum and stainless steel will balance durability against price. Complex designs and special finishes increase costs, while adding LED lighting boosts visibility and long-term savings. Understanding these aspects helps you tailor your sign to both budget and quality preferences. Explore more to make informed choices.

Key Takeaways

- Larger signs require more materials and labor, leading to increased production and installation costs.

- Material choices like aluminum, stainless steel, or brass impact the initial costs and long-term durability.

- Design complexity, including intricate details or multiple colors, raises fabrication expenses.

- Adding LED illumination enhances visibility but increases costs per letter and overall energy efficiency.

- Compliance with local regulations and obtaining permits can add significant additional expenses.

Understanding Sign Size and Its Impact on Cost

When considering channel letter signs, understanding the relationship between sign size and cost is vital. Sign size plays a significant role in determining the overall price due to several factors. Larger channel letter signs require more materials, which naturally increases production expenses. Additionally, the sign's height, typically ranging from 15 to 20 inches, can enhance visibility but also raises production costs.

The total length of the sign affects installation effort, as larger signs demand more labor and potentially additional equipment, further raising labor costs. Furthermore, local sign code restrictions might limit your size options, impacting both design and cost.

It's important to balance size with visibility needs, ensuring your sign is both effective and cost-efficient. By understanding these dynamics, you can make informed decisions that align with your budget and visibility goals, allowing you the freedom to choose the most effective channel letter signs for your needs.

Material Choices and Their Influence on Pricing

When choosing materials for channel letter signs, you'll find that aluminum offers a cost-effective option, being about 20% cheaper than stainless steel. However, if durability is a priority, opting for stainless steel or brass can increase costs but also enhance longevity and reduce maintenance needs. Consider the balance between initial expenses and long-term benefits, as thicker materials like Lexan can offer better impact resistance and lower replacement costs over time.

Cost-Effective Material Options

Although choosing the right material for channel letter signs is essential, aluminum stands out as the most cost-effective option. It's typically 20% cheaper than stainless steel, making it an attractive choice for LED channel letter signs. Aluminum's rust-resistant nature guarantees better performance outdoors, reducing long-term expenses. While stainless steel offers unmatched durability, its higher cost might not always justify the investment if you're looking for budget-friendly solutions.

For letter faces, acrylic and polycarbonate are cost-effective material options due to their versatility and lower costs. Investing in thicker materials can enhance durability, leading to fewer replacements and savings over time. By carefully selecting materials, you can balance upfront costs with longevity, guaranteeing your signage remains both affordable and functional in the long run.

Impact of Material Durability

Selecting the right materials directly affects not just the upfront cost of your channel letter signs, but also their long-term value and durability. When considering material durability, stainless steel might initially seem pricey due to its weight and installation complexity. However, it offers unmatched durability, reducing long-term replacement and maintenance costs. Aluminum presents a more budget-friendly option, being about 20% cheaper, yet still provides substantial resilience. For face materials, acrylic offers versatility, but if impact resistance is your priority, Lexan is the superior choice. Thicker materials enhance longevity, adding initial costs but saving on replacements. Opting for rust-resistant options guarantees your signs maintain their appearance, ultimately making your investment in channel letters a more valuable one.

Evaluating Design Complexity and Associated Costs

Understanding the intricacies of design complexity is essential when evaluating the costs associated with channel letter signs. When you opt for intricate designs, expect fabrication costs to rise. This is due to the specialized equipment and extra labor required to bring custom designs to life. If your design includes unique dimensions or non-standard materials, this further impacts pricing. The more complex the design, the more craftsmanship is needed, affecting not only costs but also the quality and durability of your sign.

Incorporating multiple colors or special finishes can also elevate costs by 5-10%. This is a significant consideration if you're aiming for a standout, visually appealing sign. As a business, it's important to be prepared for these potential pricing increases. By understanding how design complexity influences costs, you can make informed decisions that align with your budget, while ensuring the final product meets your quality standards.

Installation Requirements and Their Cost Implications

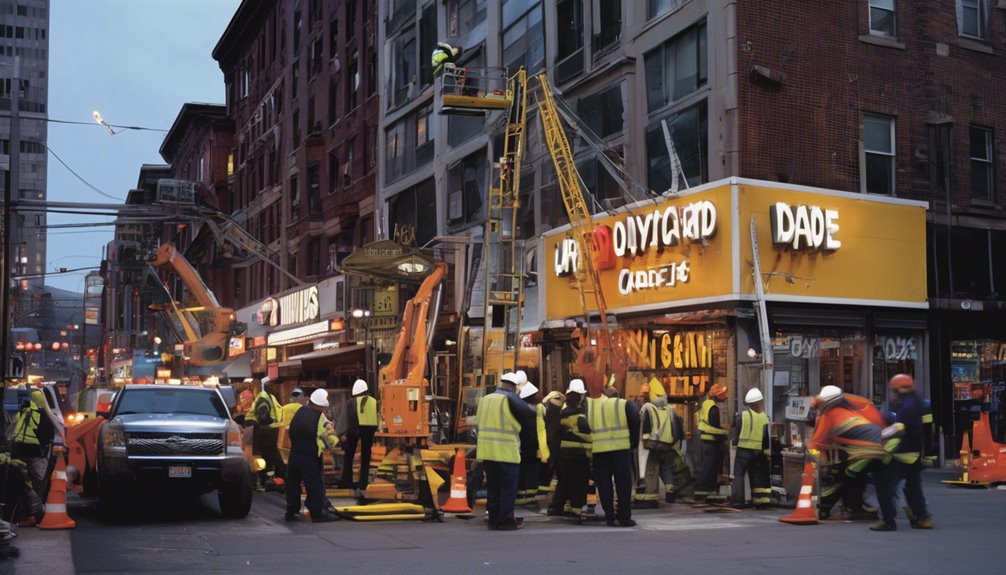

When planning the installation of channel letter signs, it is vital to take into account the various factors that can greatly impact costs. Installation costs can rise due to building height and accessibility challenges, demanding extra equipment and labor. The complexity of site conditions, like nearby trees or obstacles, can cause delays and additional expenses.

To manage these cost implications, consider:

- Mounting options: Raceway mounts are more economical, starting around $400, while wireway mounts begin at roughly $800 due to more extensive efforts.

- Local building codes and permit requirements: Compliance can add to both costs and installation time, so plan and budget accordingly.

- Proper assessment: Evaluate mounting options and site conditions beforehand to estimate installation costs accurately and avoid unexpected expenses.

Being aware of these factors empowers you to make informed decisions, giving you the freedom to plan and budget effectively for your channel letter sign installation.

The Role of Illumination in Pricing

When you're considering the cost of channel letter signs, illumination plays a vital role in pricing. Adding LED lighting typically increases expenses by $40-$50 per letter, but it enhances visibility and attracts more customers, especially at night. Despite the higher initial cost, choosing quality LEDs can lead to long-term savings through energy efficiency and reduced operational expenses.

LED Lighting Costs

LED lighting is a vital element in the pricing of channel letter signs, with an additional cost of $40-$50 per letter compared to traditional lighting. When considering LED lighting costs, you'll find that the initial purchase can greatly impact the channel letter sign cost due to factors such as:

- Quality of LED bulbs: Opting for high-quality, energy-efficient LEDs can drive up costs initially but reduce ongoing costs.

- RGB LED options: These offer a wider color spectrum and can add 5-10% to your expenses.

- Enhanced visibility and brand appeal: Effective illumination is essential for making your signage stand out, attracting attention, and reinforcing your brand.

Energy Efficiency Benefits

Although the initial investment in LED channel letter signs may seem higher compared to traditional options, the energy efficiency benefits make them a wise choice for businesses looking to save on operational costs. LED lighting reduces energy use by approximately 80%, translating to significant long-term savings. The quality LED components guarantee your illuminated signs remain vibrant and visible, enhancing your brand's presence, especially at night. While LED signs might cost an additional $40-$50 per letter, their longer lifespan and minimal maintenance requirements justify the expense. Opting for high-quality LEDs, even those slightly increasing initial costs by 5-10% due to RGB options, provides enhanced color visibility. Ultimately, choosing LED lighting supports sustainability and cuts down on unnecessary expenses.

Mounting Options and Their Effect on Cost

Choosing the right mounting option for channel letter signs can greatly impact your overall costs. The mounting options you select—raceway mounts, wireway mounts, or custom mounting solutions—play a vital role in determining installation costs. Raceway mounts are typically the most cost-effective, starting around $400, as they require less labor and fewer drill holes, reducing labor expenses. In contrast, wireway mounts, which offer a more aesthetically pleasing appearance, start at approximately $800 due to more complex installation efforts.

Custom mounting solutions may introduce additional expenses because of unique requirements and engineering. Installation costs can also fluctuate based on building height and access obstacles, which might necessitate extra equipment and labor time.

Consider these factors when choosing your mounting option:

- Raceway mounts: Cost-effective, minimal labor

- Wireway mounts: Aesthetic appeal, higher labor costs

- Custom solutions: Unique requirements, variable costs

Making informed decisions guarantees you maintain freedom in your budget.

Navigating Local Regulations and Permit Expenses

When you're planning to install channel letter signs, understanding local regulations and permit expenses is vital. Each municipality has its own rules on size, height, and placement, which can greatly impact your signage installation. Permit expenses vary, often ranging from $50 to several hundred dollars, depending on local fees. It's wise to budget for these costs to avoid surprises.

Design approvals might be necessary, requiring you to modify your sign to comply with zoning laws. This process could lead to extra time and costs, but guarantees your sign meets all requirements. Ignoring these regulations can result in fines or even the costly removal of your signage, so compliance is imperative.

To navigate this complex process, consult local sign companies familiar with the regulations. They can guide you, avoiding unexpected expenses and guaranteeing a smooth installation. Taking these steps gives you the freedom to focus on your business without regulatory worries.

Frequently Asked Questions

How Much Does a Channel Letter Sign Cost?

You're looking at a channel letter sign cost ranging from $200 to $5,000. Consider channel letter materials, installation labor costs, sign visibility factors, LED lighting options, permit fees involved, design complexity impact, maintenance expenses, and regional pricing variations.

What Is a Channel Letter Sign?

"Knowledge is power." You explore channel letter signs, discovering types like front-lit and reverse-lit. Made from aluminum or acrylic, installed flush or raceway-mounted, with LED lighting. Consider design, maintenance, and local regulations for customization freedom that enhances your brand.

How Much Does Signage Design Cost?

Signage design costs vary, influenced by current trends, logo design impacts, and typography choices. Emphasize color psychology and layout best practices to enhance branding consistency. Consider material selection and digital signage advantages for a cost-effective, eye-catching display.

How Much Does It Cost to Put a Sign on a Building?

Imagine costs as vines weaving through choices: sign installation costs range from $3,000 to $5,000. Building permits, location impact, and material choices add layers, while lighting options, maintenance expenses, design complexity, and labor rates branch out further.